Hey. Welcome to the next edition of Small-Scale Sunday from Brick + Mortar where readers get insight into the acquisition, financing, design, construction, and operations of small-scale real estate development projects.

It’s been a few weeks since my last post—a hectic few weeks as we began onboarding the various trades.

Now, we consistently have 6-10 guys on site across 3-4 trades. Much of my day is reduced to running around like a chicken with my head cut off as I attempt to keep the project on track.

Here’s a photo from last week preparing to trench our new 6” water main:

With all that’s going on, there are a number of topics worth writing about.

I’ll pick one out of the hat. One that is most pressing/urgent at the moment: working around supply chain delays.

Let’s dive in.

Some background first.

I’m treating 501 Main as an experiment in sustainable development. A major goal of the project is to reduce energy consumption and reliance on fossil fuels.

In pursuit of this, we’re electrifying heat, hot water, and all appliances. Great talking points for sure.

But implementation is another story.

The greater the electrical load on the building, the greater the power service required from the utility company.

Furthermore, for anything greater than an 800 amp service, a pad-mounted transformer is required. This adds $$$$ (easily $20k for 501 Main), not to mention the nightmare of trying to locate one on a property with no side setbacks and minimal land to spare.

Fortunately, we were able to keep the service at 800 amps (which means no EV charging for now, compact/efficient appliances, and high efficiency heat pumps). This took a slew of planning and coordination with my electrician and the utility company.

In the end, we were able to avoid a pad-mounted transformer. Phew.

But that’s just the beginning.

Then, you need to procure a meter bank that has the capacity to handle such a large electrical load. No running to Home Depot day-of for this.

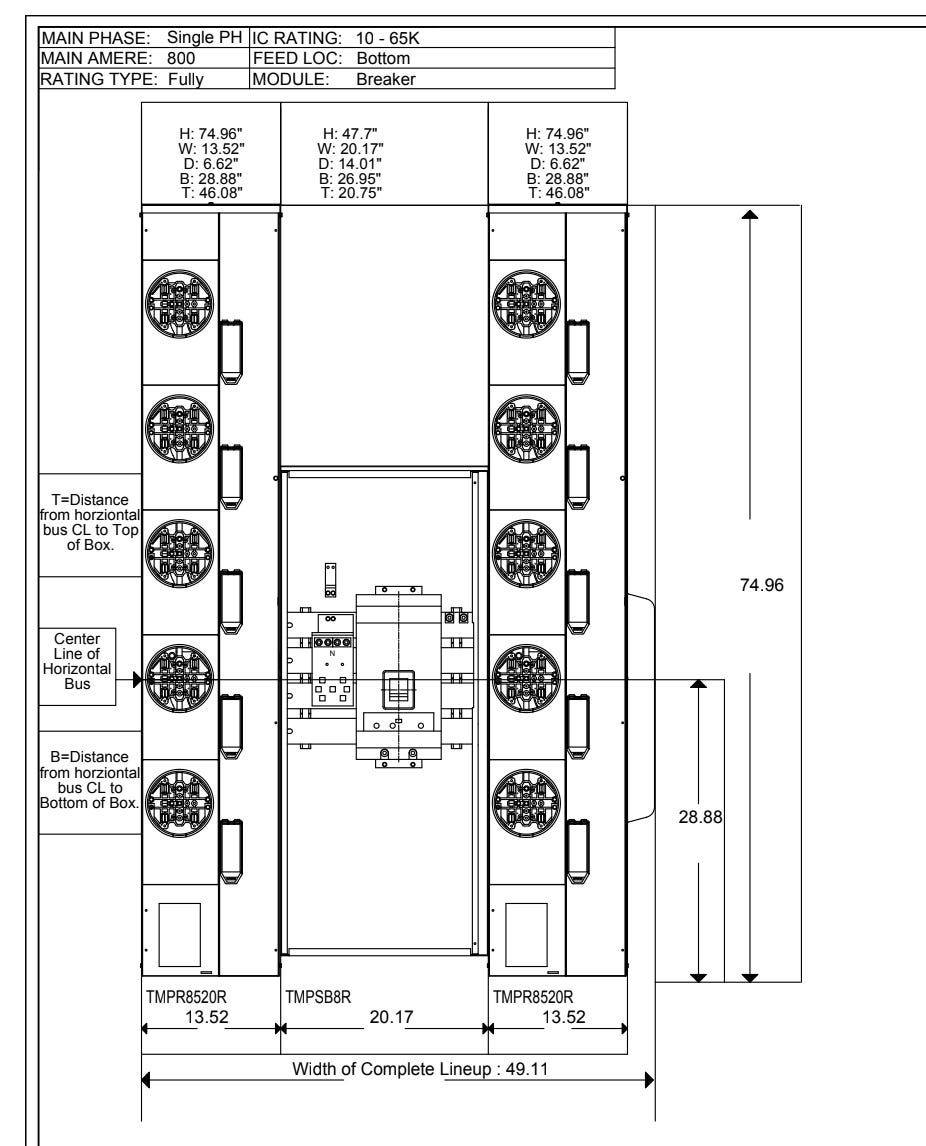

Instead, my electrician’s supplier custom designed this for our project:

At roughly 4’ x 6’, it’s a monstrosity.

And the utility company has been pushing emphatically to keep it in an area that’s highly visible from the road. Before getting the dimensions, that didn’t seem so bad. Now, having a chance to mock it up, I’m not so sure (queue the foreshadowing).

Now take a swing at the price.

$17,000.

SEVENTEEN THOUSAND DOLLARS. Just in materials, not including install. That’s mind boggling. Two years ago, we would have paid 1/4 of that.

But ok. A necessary evil. This is just another cost of doing business, I can accept that.

Until we get to the lead times.

My electrician knew this was going to take a minute for the manufacturer to build so he ordered it in January—months before the project broke ground.

With an 6-8 month lead time, we should have gotten it before we needed it in September. At the 6-month mark in June, my electrician reached out to the supplier to confirm delivery.

Turns out, there was a massive miscommunication. The order never went through.

So now, we would be looking at 6-8 months from the new order date for delivery—January 2023 was quoted.

While that was painful to hear, we worked out a path forward where this didn’t hold us up.

With a target of January 2023 to open doors, this would just be one of the last items completed. We could do all rough-ins and finish work and come back to install the meter bank at the end. Not ideal due to added complexity for testing and temporary power, but certainly doable.

So we kept plugging away.

That is, until this past Friday.

We get an updated delivery date: May 2023.

Holy f***. That would delay opening by 4-5 months. And cost us $50k in lost revenue.

We immediately meet up for a pow wow. First, we call my electrician’s four other suppliers. All are quoting 12-month lead times. No dice.

What if we think outside the box?

Say, 10 single meters with individual disconnects. The Home Depot special.

We call the inspector. He doesn’t approve. Apparently, there’s a “6 passes to the hand” rule where, in an emergency, the fire department needs to be able to shut off all power with 6 motions. Totally fair, but nonetheless disappointing.

I keep pushing for more creative options. My electrician eventually gives up. I don’t. There must be another way.

I go back to my office (aka my truck, a laptop, and a Verizon hotspot) and start calling suppliers, trying to find another solution.

After calling 30-40 suppliers, I discover a solution that may work: two Schneider Electric Square D 5-gang meter packs with two 400 amp disconnects. Not immediately available, but only a 6-12 week lead time.

I take this back to my electrician. He thinks it can work and is able to get inspector and utility company sign-off.

Ok, great. Only question remaining is does the new setup fit in the space identified by the power company?

So yesterday, I go to the site and measure.

No, it doesn’t—we need to find a new location. Perhaps this isn’t a bad thing since it gives us a reason to reposition away from public eye.

But, it’s the weekend and no one else is working (crazy, right?). I’ll have to wait until Monday until I discuss with electrician and power company. Hopefully, we can convince the utility to allow us to bring the meters inside the basement.

Although I don’t want to jinx it, there is a silver lining here. Total cost of the new setup that I patched together is $10k. So, if it works, it may have been worth the headache.

In situations like this, it’s easy to pass the blame. Why did my electrician wait 6 months to confirm the original order? Why can’t the manufacturers pick things up a notch?

But, really, all of this falls on the GC. As a GC, you need to anticipate and plan for supply chain delays (this is a similar scenario to the windows we’re still waiting for. Only 5 weeks to go though!).

Lead times are constantly changing. A 10-gang meter pack that once took 2-3 weeks to deliver pre-pandemic now takes 12 months. It’s the GC’s responsibility to keep a pulse on supply chains.

And it’s not overly complicated, either. Really, it just means staying up-to-date with your subs and suppliers. Have materials identified before breaking ground and create a calendar of when to order various items based on input from the folks in the trenches. Then, check in regularly.

I suppose that’s just basic construction management. But we all have to learn somehow.

Thankfully, I’ve managed to stay organized enough to get by. And I’m fortunate to have a stellar team of subs and suppliers that make up for my deficiencies.

But, rest assured, with each toe stubbing like this, my processes and systems get more and more refined.

“Fool me once, …”

Until next time.

— Jonah 🧱

P.S. Want to connect? Find me on LinkedIn and my projects on Instagram.

P.P.S. To end on a positive note, our rear balconies are coming along!

Great read and absolutely key for future lessons learned.

You have all of my empathy. Nothing like realizing some piece of electrical equipment was never ordered and it having an 8 month lead time. Been there. It's not fun. Glad you found a solution that might work!